If you’ve been following our Project Samurai, you’ll recall that we ran into a brick wall when we couldn’t get the engine to fire up and run properly. Endless hours were spent chasing problems, eventually taking the motor apart to check everything possible. We were hunting down potential problems in the wiring harness and with the timing.

Frustrated, we took the Suzuki to Ken Neal, a close friend at Bullet Proof Diesel, to let him have a look. Ken had the wiring diagrams that we needed. He grabbed a test light and ran a few basic checks. It was determined that the computer was working fine. He then used a compression tester made for diesels and found the compression was extremely low.

Wes Holmes, the owner of Project Samurai, was beginning to second-guess his work. "Is the timing belt correct? Is the crankshaft degreed correctly? Were the marks transferred correctly?” And lastly, “Was the motor he purchased from Quality German Auto any good?” When he got the motor, the tag showed only 60,000 miles on this engine.

Previous Project Samurai Stories

Part 10 – TDI Engine Trouble

Part 8 – Completing Interior and Controls

Wes then remembered a vehicle he was working on once when he first became a mechanic years ago. He was sent out on a mobile call for a "no-start" situation. It was extremely cold in Colorado that day, 15 below, as a matter of fact. He checked for spark and it was good. He assumed the car was flooded but he still couldn't get it to start. He checked the compression and it was extremely low, under 85 pounds. He thought maybe it had jumped time. He checked the timing belt and it, too, was good.

So he had the vehicle towed into the shop. Upon arrival at the shop, the owner opened the trunk to get a few things out, and the shop owner noticed several cans of ether scattered in the trunk. When asked about them, the lady replied that her boyfriend used the ether to try to start the car. The car acted like it was going to start, so he kept spraying more in.

Wes was instructed to pull the plugs out and put oil in the cylinders; he then put the plugs back in and tried to start the engine. It started right up. The oil was washed off of the rings from the ether, creating a low-compression reading.

Now, what does this story have to do with our diesel, you may ask? Our diesel engine had probably been sitting for several years at the bone yard and then set for several months at our shop, allowing the oil rings to drain down, making a low-compression condition (360 lbs.).

Wes added oil to the cylinders and then reinstalled the glow plugs. The compression was checked after adding the oil and then the compression was about 500 pounds steady. Still, the engine would not start.

Wes called Charlie at Kerma TDI and had him run a few checks on the computer and wiring harness. Then these items were shipped off; once there, Charlie modified and chipped the computer, giving increased performance, and then sent the harness and computer back.

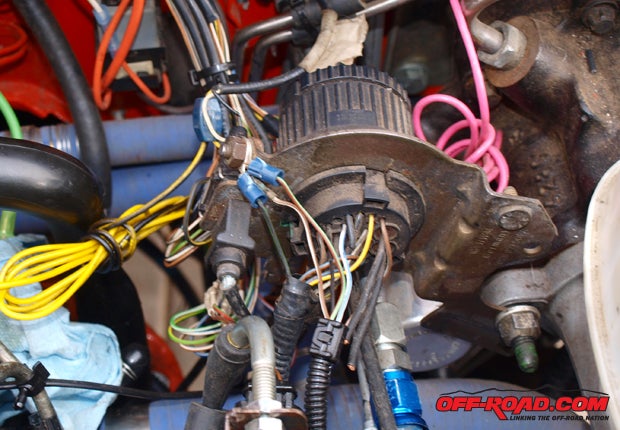

Anxious to hear this baby fire up, Wes promptly installed the computer and harness. Surprisingly, on the wiring harness, there's only a few items necessary for a computer controlled diesel.

Wes had only three wires to hook up: ignition power, ground, and a ground that the computer supplied. Kerma TDI eliminated all of the wires Wes did not need, such as cruise, anti-lock, etc., by customizing the computer.

But ... the engine still would not start. Charlie then suggested we check the harness plug that is known to be a problem of that year model.

Aha! Wes found ONE of our gremlins: an intermittent open circuit to the injection pump. Wes cut and soldered the wires to the injection pump, eliminating the plug.

Still, the engine would not start!

Back on the phone with Charlie; Wes checked for ignition power at the injection pump shutoff solenoid, double-checked our grounds and the ground that the computer supplies. It can't get much easier than that.

Everything checked out good. So why was it still not starting? Charlie suggested since the fuel is getting to the pump then maybe the injector pump might be bad. Keep in mind that he's doing all this over the phone.

We then called Thomas at Quality German Auto regarding the injector pump. He felt pretty confident that the pump wasn't the problem, but he said for us to send it to him and he would give us another pump. But, before we sent him the pump, he suggested we take a piece of clear hose and hook it up to the injector pump. This would allow us to see the fuel being delivered to the injector pump and to watch for air. Sure enough - we sew air.

Starting from the motor and working our way back to the fuel tank, we started looking for loose fittings and tightened everything along the way. Wes found no loose fittings or any leaks, so he hooked up a fuel gauge to the FASS fuel pump and it showed only one pound of pressure. But yet when Wes went to bleed the injectors, the pump had so much volume, the injectors would bleed easily. Wes had welded an AN fitting to the fuel tank (similar to a bulk head fitting). This line went inside the fuel tank at the top and then had a metal line that continued to the bottom of the tank. The metal line inside of the tank has a 90-degree bend in it going to the bottom of the tank to pick up fuel. Unknowingly, this line developed a hairline crack in it when it was bent. Air in the fuel line of a diesel is a bad thing. The bent line was replaced and we re-bled the injectors to keep the clear hose on the pump. The motor started instantly once the air bubbles went away!

A BIG thanks to Ken Neal at Bullet Proof Diesel, Thomas at Quality German Auto, FASS Fuel Pumps and especially Charlie at Kerma TDI.

Now the opportunity came to drive the Samurai down the street, which Wes did so sideways to show off the Howe Performance Rear Steering – and it felt good! And then, of course we had to raise the rpm and drop the clutch light up the pair of 37-inch Falken tires, leaving twin stripes down the street for about 15 feet. Keep in mind this was in high range with a small, four-cylinder 1.9-liter diesel. It felt more like a small V-8. Wes knew it was a good thing he used a 9-inch rear end and stout 35-spline RCV axles.

A word about the computer controlled engine. The drive-ability of a computer-controlled engine vs. a pure mechanical setup comes from the ability to have total control over all the engine operating parameters, which gives great flexibility over a wide variety of driving conditions. For example, the timing and fuel in a mechanically controlled injection pump generally has a linear response with load and rpm. The computer-controlled version can vary these to better suit the desired response and environmental conditions. In the hands of a skilled programmer the results are like night and day. Charlie explained it like this: the old mechanical stuff has springs to tension and screws to turn. The ECU uses maps, volts and feedback in the place of nuts and bolts. It takes its own tools and skillset to manipulate, just like you need a screwdriver or torque wrench for other jobs. However, just like adjusting dwell on a distributor or jets in a carb, there's a right way and a wrong way to do it if you want your engine to run the best it possibly can.

With the 37-inch Falken tires and the 4.88 gears we got from Randy's Ring and Pinion, we were running down the highway, roughly turning 2300 rpm at 65 mph, and were able to step on the gas and “pass at will” once the turbo kicked in.

FINALLY, OFF-ROAD!

After getting off the highway and getting the feel of dirt under the Samurai, we left it in high range. The throttle response was incredible! Our first trip in the dirt was in fairly hard-packed sand, and here we still had the transmission in the highway cruising mode, yet the results is it still felt powerful and torquey. Was it possible that we didn’t even need to a second transfer case for off-roading? Then Wes dropped it into the soft sand where the torque on this little motor really shined. It absolutely pulled like a small V-8; it’s hard to believe this motor is so small.

As Wes traveled down the trail, it was time to pick out a hill and see how the low range worked. Wes noted that it was really nice to steer with 2 1/2 turns lock to lock. That meant not whipping the wheel from one side to the other as he went through the tight trails. The high-volume power-steering pumps really showed their assets in the tight stuff.

The suspension was extremely soft; the spring rates were a little off, but that’s to be expected when you first build a car. Still, the car was extremely agile and the rear wheel steering was extremely smooth and controllable off-road.

It was really nice going through tight trails because the car is small enough to give that go-kart feel. Inside the cab, Project Samurai is really neat. All the levers are at hand, transfer case shifter’s right there, and the second transfer case is close as well. With four people in the car with the added work to the floorboards, even the people in the back don’t have their knees against their chest. The extra work was worth it.

“With our special transfer case setup, we have high range, low range and double low. Anyone with a 4x4 knows that about high ranges and low ranges, but they might be confused as to our double low,” Holmes explained. “We had two transfer cases hooked together. That’s what made this Toyota coupling to the Volkswagen TDI motor such a great marriage. It’s because of the fact that on the highway you have direct gearing, while in the dirt you have low range and in the nasties, and you have a double low and a second transfer case that will give you the flexibility of a snail crawling.”

The first hill Wes approached during testing was rutted out and soft, but he realized this was just a shakedown run. “I put the car in low range and headed up in second gear at probably five miles an hour,” he said. “The turbo kicked in and up the hill we went in second gear. I was astounded. I could have easily done it in third. Unbelievable!

“After getting to the top of the hill. I dropped back into the wash, where I wanted to find out what the gearing really felt like. I ran through the gears at a top speed of 50 mph in low range. So then I dropped it into low-low, where I believed that fifth gear felt like a top speed of 20 miles an hour. It’s amazing with double low at idle in fifth gear; it just crawls right along in deep sand. And unlike a typical diesel, the 1.9 works without black smoke blowing out of it. This is where the computer-controlled TDI really shines. You don’t have all that sooty smoke barrel out of it every time we hit the throttle. When I hit the hill, I looked in the mirror and all I saw was dust from my wheel spin.

Holmes kept on testing the vehicle at a variety of different speeds in the dirt.

“Now we were on the trails doing moderate speeds from 20 miles an hour to 30 and occasionally would hit an open spot where we could hit 50,” he said. “We were bottoming out prematurely and we had some body roll due to the fact that the sway bars were not adjusted yet. These are all things we will take care of the next time out.

Previous Project Samurai Stories

Part 10 – TDI Engine Trouble

Part 8 – Completing Interior and Controls

Oveall, the first off-road test was a success. After the long build and all that challenges it presented, Holmes was pleased it was finally trail-ready.

“We stopped and were standing back and looking at the car, thinking about the amount of work we put into it and analyzing what we’ve accomplished. The motor/tranny/transfer case marriage was a total success. The suspension will need some fine-tuning still. The torque and horsepower knocked the ball out of the park; the torque versus the weight and the fuel mileage is something no other vehicle could claim.

“Looking back at everything, I think I would rate this thing at a 10 for the drivetrain, a motor choice at 10, and remain absolutely glad that we did not use the mechanical injection motor overall. The motor with computer controls is brilliant. The one thing genuinely stands out the most: this little 1.9 motor actually had more horsepower than what I could ever imagine. In my wildest imagination, I never believed such a little motor would put out the torque, horsepower and rpm so smoothly and still have outrageous gas mileage. There are other people who have used the Cummins and others, but I doubt if they had the success that we did.

What we ended up with when all the smoke is cleared is an incredibly light four-door off-road vehicle with a great suspension and a motor that borders on legendary. Project Samurai is a vehicle comfortable cruising on the road that will get great mileage, yet we can drop that baby into low-low and crawl over some of the meanest trails. Did we make a Jeep killer? Holmes exclaims: “Hang up the wanted poster.”

Your Privacy Choices

Your Privacy Choices