Our Lexus GX 470 is starting to take shape, but we still have quite a few pieces to get installed. With the Icon Vehicle Dynamics suspension upgrades installed, and our rear springs converted thanks to the Metal Tech 4x4 kit, we decided to shift our focus to the Metal Tech 4x4 components for our GX.

We desperately want to toss on our new 33-inch Nitto Ridge Grappler tires and Icon Alloy Alpha wheels and get those silly stock tires off, but even with the suspension lift we still needed some additional trimming in the front wheel wells for a better fit. So prior to performing a body chop mount at our local 4x4 shop SoCal SuperTrucks, we plan to install our Metal Tech 4x4 front bumper, Pegasus Rear Bumper and the OPOR sliders from Metal Tech.

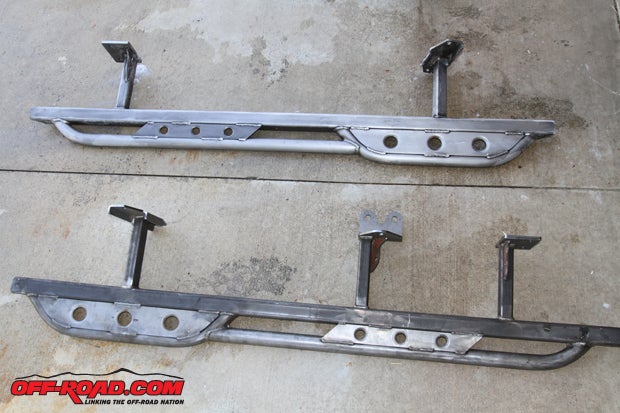

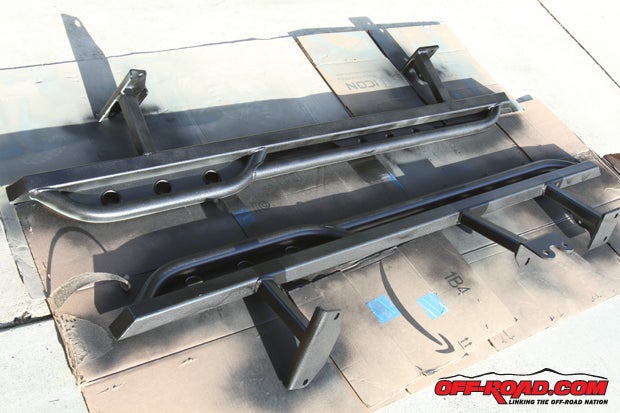

MetalTech 4x4 has been operating out of its home base in Newberg, Oregon, for 17 years, making a wide variety of off-road parts for Toyota trucks and SUVs. After seeing some of the companyís gear on Toyota Land Cruisers and the handful of GXs weíve encountered on the trails, we decided to outfit our GX with Metal Tech parts because they look good but also because of their no-cut front and rear bumper options and stout rock sliders. We went to work on the sliders first. MetalTech 4x4 offers the option to powder coat its sliders or get them in bare steel, and we opted for the bare route simply because we wanted to rattle-can paint the sliders. Powder-coating sliders is a great option for many, but in our experience rattle-canning them can be easier for touch ups when they get dinged on the trails. We decided to have the front bumper and Pegasus rear bumper powder coated but the sliders shipped in bare steel simply because we expect more wear and tear on the sliders overall. One thing to note about getting these parts, or any other, in bare metal is the parts come with additional work up front prior to installation.

Metal Tech 4x4 owner Mark Hawley is an off-road enthusiast but also a skilled fabricator, and he offered some great tips on how to properly prep the bare metal for our sliders. When the parts are shipped thereís a grease coating on the metal to protect it from rusting in transit. This needs to be completely removed prior to painting; otherwise the paint wonít be able to properly adhere to the metal. Hawley suggested buying cheap powder laundry detergent, as the alkaline in the soap helps remove the grease from the metal. We found the right stuff at our local 99 Cent store. We knew we were on the right track when the box stated the CAUTION: EYE IRRITANT.

Using a Scotch Brite pad (we used Green, but Red would work too) and a bucket of water mixed with our detergent (keeping soapy mixture very thick so it will be gritty), we scrubbed down the sliders thoroughly, washed the soapy mixture off and double-checked the surface again to make sure it was clean. After the final rinse, we wiped down the sliders completely to remove any moisture prior to paint and let them air dry.

Once fully dried, we applied two stages of paint on the sliders. First, we used a self-etching primer and applied two even coats and then allowed them to fully dry. Then, we applied our black paint. We opted for Rust-oleum Truck Bed Coating because it features a gritty finish once dry to provide grip on the sliders, which double as steps to enter and exit the vehicle or load gear on the roof. Expect the painting and cleaning process to take a few hours.

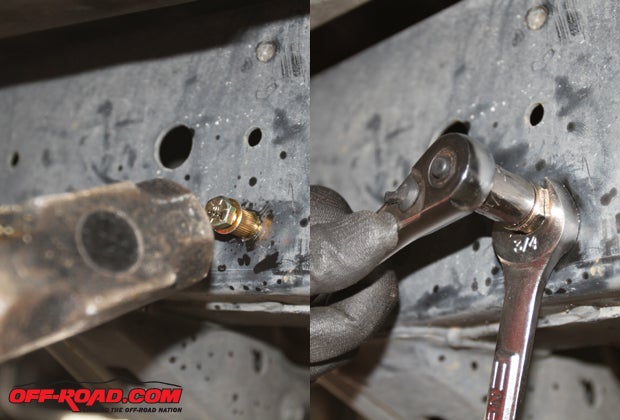

The installation of the sliders is fairly straight forward, though there are a few variations if your GX is equipped with the KDSS system. Plan on setting aside a few hours for slider installation itself. They arenít technically difficult to install, but they do require a few small holes to be drilled into the frame, so making sure placement is correct is very important.

Follow along the images below for a basic overview of the installation, but Metal Tech 4x4 does include comprehensive instructions on every step.

MORE GX 470 STORIES

Rear Spring Conversion and Icon Suspension Upgrade

Icon Vehicle Dynamics Front Suspension Upgrades

Why Weíre Building a Lexus GX 470 Trail Rig

SOURCE

Metal Tech 4x4

800/839-0684

MetalTech4x4.com

Your Privacy Choices

Your Privacy Choices